which is a type of machine safeguarding

Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. Fixed Adjustable Self-Adjusting Guards.

In August 2018 Google Incorporated Voice Navigation In The Navigational Platform For Pu Navigation System Information And Communications Technology Navigation

The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the appropriate machine safeguarding method for the.

. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. 3 Fixed adjustable access guard. Each class contains sections on equipment operations hazards case studies and more.

A machine running within its acceptable conditions can become fatal to humans present. A Servicing or maintenance is not hazardous for employees. Restrain or withdraw the operators hands from the danger area during operation.

There seem to be as many hazards created by moving machine parts as there are types of machines. There are five 5 general types of machine safeguards that can be used to protect workers and personnel in the immediate vicinity of machinery. Adjustable guards that can be moved or placed depending on the operation.

You should try to have these before any other types of machine guarding. Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines. A safety device may perform one of several functions.

Basics of Machine Safeguarding. The goal for machine guarding is simple. Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed.

One may also ask what are the 2 types of primary safeguarding methods. They should be a close fit robust and withstand speed vibration impact etc. Fixed guard on bandsaw.

Types of Machine Guarding Restraint Devices. Guard opening and its distance from the dangerous part should be fully safe. Types of machine guarding.

Which of the following is a type of machine safeguarding punchink feeding and ejection methods point of operation in-going nip points Feeding and ejection methods is a type of machine safeguarding. Methods of Machine Safeguarding. Plus interlocking guards automatically shut off a machines power source when employees open them.

It doesnt depend on machine motion to function. Prevent contact with the hazard. This presentation includes intermittent practice quiz questions to prepare for the final written exam included with the course.

The threat is not limited to a machines abnormal behavior. Types of Machine Guarding. Herein what are the most common types of machine guarding.

Safeguards are essential for protecting workers from needless and. A fixed guard is a simple device attached to the machine designed to cover hazardous mechanical motions and prevent entry from hands or fingers. Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time.

Some prominent characteristics of machine guarding include the following. Fixed guards cannot be removed easily without the use of tools. Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

If there is an obstruction preventing it from descending its full predetermined distance the control circuit does not actuate the machine cycle. 2 Fixed limited access guards. Primary Safeguarding Methods Two primary methods are used to safeguard machines.

Fixed guards like the photo of the fan guard around the blades in the picture above. The electromechanical sensing device has a probe or contact bar which descends to a predetermined distance when the operator initiates the machine cycle. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal Regulations CFR 1910 Subpart O Machinery and Machine Guarding as detailed below.

Safeguards are essential for protecting workers from these preventable injuries. There are four main types of car protectors. Machine guarding is a method to protect persons from the danger posed by machine parts especially moving parts.

Machine safeguarding helps protect workers from preventable injuries in all three areas. A well-designed fixed guard will also prevent the operator from reaching over or under the guard into the point of operation. It must be substantial enough to withstand the machines impact.

According to OSHA poor machine guarding leads to about 18000 amputations. B Maintenance is minimal and. There are many ways to design and use machine safeguarding.

Guards these are physical barriers that prevent contact. OSHA Safety and Health Information Bulletin SHIB January 25 2013. However when employees need to pop the guard open to deal with maintenance and repairs interlocking guards are very accommodating.

An interlocking guard provides a reliable barrier over moving machine parts. Various types of machine guards available for machine guarding. Machine guarding refers to protections on or around machines to safeguard human operators from hazardous conditions or injury.

This is the preferred type of guard. All of the above Which of the following is a type of machine safeguarding. A fixed guard is the permanent part of the machine.

Basics of Machine Safeguarding. Any machine part function or process that may cause injury must be. A fixed guard is a permanent part of the machine.

Machine guards sometimes referred to as safeguards are the protective devices that cover the hazardous or injurious parts of engineering machines. The most common types of machine guards are. There are different types of machine guards.

Most usable machine guards are described below. Our Machine Guarding Safety Training course is regulation compliant and our online version fulfills classroom training requirements. Which of the following is an exception to the general rule for safeguarding to prevent hazards during servicing and maintenance of machines.

Require the operator to use both hands on machine controls thus keeping both hands and body out of danger or provide a. Their suitability should be selected. Contents hide 1 Fixed guards.

Machine guarding is a safety device on or around production equipment or other technical equipment consisting of a shield or device that covers hazardous areas of a machine to prevent contact with body parts or to avoid hazards like splinters or sparks escaping.

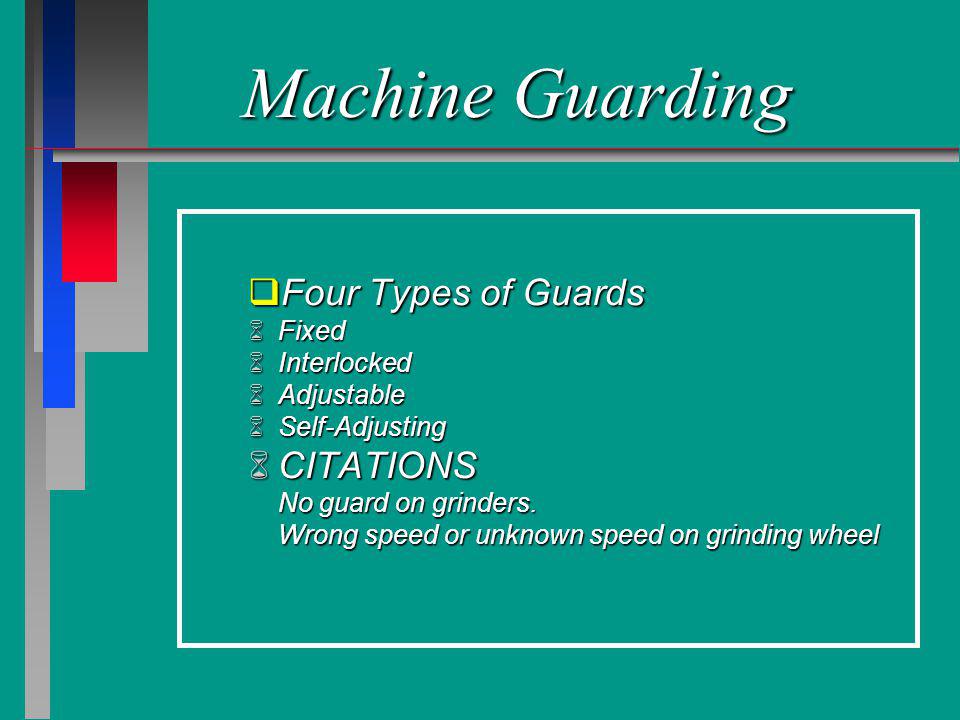

Four Types Of Fixed Machine Guards

Machine Guarding Four Types Of Guards Citations Fixed Interlocked Ppt Video Online Download

Black Decker Dcm600b 5 Cup Coffee Maker For Sale Online Ebay Coffee Maker 5 Cup Coffee Maker Black Decker

Crane Balancing Act Truck Cranes Crane Construction

Check The Importance Of Machine Guarding

Mat Foundation And Its Types Mat Foundation Deep Foundation Foundation

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Enterprise Content Management Market Size Outlook Trends And Forecasts 2018 2024 Enterprise Content Management Content Management Marketing

Safeguarding The Mold In 2021 Molding Plastic Molds Mold Making

Four Types Of Fixed Machine Guards

Wholesale Commercial Gym Equipment 6 Important Items To Look For When Buying Gym Equipment Gym Commercial Gym Equipment Gym Equipment

Best Espresso Machine Under 200 Jan 2020 Updated Top 10 Reviews